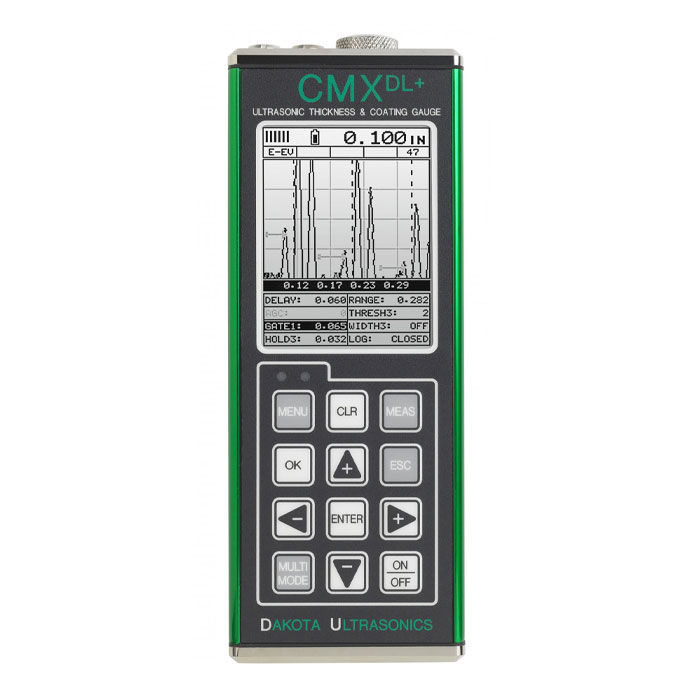

DAKOTA ULTRASONICS CMX DL+ THICKNESS

DAKOTA ULTRASONICS CMX DL+ THICKNESS v2.0 gauges have all the features of the base CMX models plus a full-featured A-scan display with RF and rectified display options. If you want a DAKOTA ULTRASONICS CMX DL+ THICKNESS device with a gain of 110 dB for high flexibility in all types and applications of converters, ask for it with the best quality and price from our experts.

MME Shopping Event

Hurry and get discounts on Most of MME Products up to 20%

Call for Price

DAKOTA ULTRASONICS CMX DL+ THICKNESS SOUND SOLUTIONS

DAKOTA ULTRASONICS CMX DL+ THICKNESS v2.0 gauges have all the features of the base CMX models plus a full-featured A-scan display with RF and rectified display options. The CMX DL+ is equipped with 3 completely independent ports (start, stop, width, and threshold). Featuring a 110dB gain range for greater flexibility in a variety of transducer types and applications. 50V (100 – 200V) selectable gain or cutoff.

Enhanced Flexibility with DAKOTA ULTRASONICS CMX DL+ THICKNESS Color Version

The color version offers the ability to rotate vertically or horizontally to increase the A-scan field of view. Our Java-based DakView for PC or MAC OSX makes this kit a true CMX Series Cadillac. If you want a DAKOTA ULTRASONICS CMX DL+ THICKNESS device with a gain of 110 dB for high flexibility in all types and applications of converters, ask for it with the best quality and price from our experts.

Handheld CMX DL+ Thickness Gauge with Large LCD Display for Easy Field Use

The portability of the DAKOTA ULTRASONICS CMX DL+ THICKNESS is one of its main features. It is a handheld gadget that is easy to transport, making it ideal for usage in the field or on the manufacturing floor. It also boasts a large, easy-to-read LCD display that offers precise thickness readings even in low-light environments. Because of this capability, it is a useful tool for workers that need to collect measurements fast and efficiently.

Versatile Thickness Measurements with DAKOTA ULTRASONICS CMX DL+

The adaptability of the DAKOTA ULTRASONICS CMX DL+ THICKNESS is another advantage. It may be used to measure the thickness of a wide variety of materials, including metals, polymers, and composites, making it an indispensable tool for companies that deal with a wide range of materials. Furthermore, this device has multiple measurement modes, including pulse-echo, echo-echo, and dual-element, allowing users to choose the best mode for their particular application.

DAKOTA CMX DL+ THICKNESS FEATURES

- For thickness or bottom & amp; error detection.

- Dual Channel: Dual pulse generator and receiver.

- pulse repetition frequency up to 250 Hz.

- layer thickness measurement.

- Refresh rate display 25Hz.

- temperature compensation.

- Range meters from 0.025 to 48 inches (thickness) …Resolution±0.001 inches.

DAKOTA ULTRASONICS CMX DL+ THICKNESS SPECIFICATIONS

- Size: Width (2.5 in/63.5 mm), Height: (6.5 in/165 mm), Depth: (1.24 in/31.5 mm), Weight:13.5 ounces (with batteries).

- Keyboard: Membrane switch pad with twelve tactile keys.

- Operating Temperature:14 to 140F (-10C to 60C)

- Case: Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed).

- Data Output: Bi-directional RS232 serial port. Windows® PC interface software.

- Display (Two Options): 1/8 VGA grayscale display (240 x 160 pixels). Viewable area 2.4 x 1.8 in (62 x 45.7 mm). EL backlit (on/off/auto). 25 Hz screen refresh rate. 1/4 VGA AMOLED color display (320 x 240 pixels). Viewable area 1.7 x 2.27 in (43.2 x 57.6 mm). 120 Hz screen refresh rate.

- Measurement Modes: Coating Off: Pulse-Echo (P-E), Coating On: Pulse-Echo Coating (PECT)

- Temp Comp: Pulse-Echo Temperature Compensation (PETP), Thru-Paint: Echo-Echo (E-E), Thru-Paint Verify: Echo-Echo Verify (E-EV), Coating Only: Coating (CT), Pulser: Dual square wave pulses.

- Receiver: Dual receivers – manual or AGC gain control with 110 dB range. Adjustable damping (50-1500 ohms), Timing: Precision TCXO with single shot 100 MHz 8-bit ultra low power digitizer.

- Line Power: USB to PC or power outlet, Three 1.5V alkaline or 1.2V NiCad AA cells, Alkaline: grayscale 35 hrs, color 12 hrs, Nicad: grayscale 10 hrs, color 5 hrs, NI-MH: grayscale 35 hrs, color 12 hrs, Power saving DIM (color), Auto power off if idle 5 min, Battery status icon.

- Range: Pulse-Echo Mode (P-E): (Pit &law Detection) measures from 0.025 48.0 inches (0.63 to 1219.2 millimeters).

- Pulse-Echo Coating Mode (PECT): (Material, Coating, Pit & Flaw Detection): Material: 0.025 to 48.0 inches (0.63 to 1219.2 millimeters). Coating: 0.001 to 0.100 inches (0.01 to 2.54 millimeters).

- Pulse-Echo Temp Comp Mode (PETP): (Pit &law Detection) Auto temperature compensation – measures from 0.025 48.0 inches (0.63 to 1219.2 millimeters).

- Echo-Echo Mode (E-E): Thru Paint & Coatings) measures from 0.100 to 6.0 inches (2.54 to 152.4 millimeters). The range will vary +/- depending on the coating.

- Echo-Echo Mode (E-EV): Thru Paint & Coatings) measures from 0.050 to 1.0 inches (1.27 to 25.4 millimeters). Will vary based on coating.

- Coating Only Mode (CT): (Coating Thickness) Measures from 0.0005 to 0.100 inches (0.0127 to 2.54 millimeters). The range will vary +/- depending on the coating.

- Resolution: +/- .001 inches (0.01 mm), +/- .0001″ inches (0.001 mm)

- Velocity Range: .0122 to .7300 in./ms (309.88 to 18542 meters/sec)

- Calibration: Single and Two point calibration option for material & coating, or selection of basic material types, Units: English & Metric.

- Large Digits – Standard thickness view. Digit Height: 0.700 in (17.78 mm). Color 0.565 in (14.35 mm).

- A-Scan – Rectified +/- (flaw view), RF (full waveform view), Pulse Repetition Frequency – 250 Hz.

- A-Scan Refresh Rate – B&W 25 Hz, color 60 Hz, B-Scan – Time-based cross-section view. Display speed variable (10 to 200 readings per second). Adjustable display speed, Scan Bar Thickness – Speed 33 Hz. Viewable in B-Scan and Large Digit views, Repeatability Bar Graph – Bar graph indicates the stability of the reading, Feature Status Bar – Indicates features currently active.

- Log Formats: Grid (alphanumeric) Sequential (auto identifier), Capacity: 4 Gb internal SD card, Screen Capture: Bitmap graphic capture for quick documentation (.tif), OBSTRUCT to indicate inaccessible locations.

- Transducer Types: Dual/Single Element (1 to 20 MHz). Contact, matching layer, delay line, pencil configurations, LEMO 00 connectors, Standard 4-foot cable, Custom transducers & cable lengths available for special applications.

- Output: Direct USB-C 1.1 PC connectivity, Transducer Connections: Two LEMO 00 connectors.

- 2-year limited, Factory calibration traceable to NIST & MIL-STD-45662.

- Auto probe zero, recognition and temperature compensation, 64 custom setup configurations, High speed scan up to 50 readings per second, Audible alarm with hi/lo limits, Built-in differential mode for QC inspections.

Further explanation

single element contact transducer dakota AND microdot nonmagnetic single element contact

Microdot connectors are used in ultrasonic testing equipment to allow for the simple connection and disengagement of probes and transducers.

Dakota Ultrasonics Corporation manufactures a variety of single-element contact transducers with Microdot connectors. These transducers are specifically intended for use in non-destructive testing applications where detecting defects or flaws in materials without causing damage is critical.

The Microdot nonmagnetic single-element contact transducer is a type of specialized contact transducer that is intended for use in applications where magnetic interference is a concern. These transducers have a nonmagnetic housing and are commonly employed in locations where magnetic materials could interfere with the accuracy of the test findings.

Dakota Ultrasonics Corporation manufactures a wide range of high-quality single-element contact transducers, including those with the Microdot connector and those for use in nonmagnetic situations. These transducers are commonly used in industrial applications to measure thickness, detect flaws, and perform other non-destructive testing.

You must be logged in to post a review.

Brand

Dakota

Dakota

Dakota Ultrasonics is a manufacturer of high-quality industrial ultrasonic testing equipment for the petrochemical, aerospace, power generation, automotive and related industries. If you have questions, need technical support, or request custom items, the Dakota Ultrasonics team is available and happy to help.

Datasheet

Specifications

Specifications

Related Products

Extech TKG150 Ult Thickness Gauge/Datalogger

In stock

Reviews

Clear filtersThere are no reviews yet.